What Is a Cable Hoist and How Can You Use One?

With uses in the mechanical, shipping, transportation, and construction sectors, cable hoists are extremely versatile pieces of equipment that have applications in a vast array of projects. If you suspect that you could benefit from a cable hoist, read on to better understand how they operate and the benefits they offer. This will empower you to make an informed choice if you decide to add one to your arsenal.

Cable Hoist Basics

A cable hoist is a form of overhead mechanical system consisting of a cable and a hoist system. When a weighted object is suspended from the cable, it moves vertically up and down and can be controlled by the operator. The hoist system can also be automated, allowing for fast and accurate movements of heavy loads. Since the cable hoist doesn’t use any kind of power source, it’s a completely manual system. The operator controls the hoisting motion by using pulleys and winches. A powered cable hoist uses a steel cable that is connected to a drum and pulley system.

Working Principles Behind Cable Hoists

When the cable hoist is operating properly, the hook will move vertically up and down, transferring motion from the cable to the hook and load. The hook moves up and down as the cable winds around it, depending on the amount of force applied by the operator. As the hook rotates, it connects to a pulley. The pulley is connected to the drum, which moves it horizontally. The drum is connected to the load, so when the operator activates the hoist, the load moves in response to the operator’s motion.

Uses for a Cable Hoist

No matter how high you’re working, you can save time and effort by using a cable hoist. These systems are designed to provide reliable lifting and transferring of loads that would be difficult or impossible with conventional hand tools. For example, a cable hoist can be used for hauling and moving construction materials, moving and installing electrical or plumbing fixtures, or retrieving items that are out of reach, like garden tools or firewood. It can also be handy for working on your car. This makes them an ideal solution for doing big rig repairs, installing exhaust systems, or even changing a tire.

Moving Heavy Loads With Cable Hoists

A lot of jobs involve moving heavy objects, like building materials and parts. When you need to move these items over long distances, a cable hoist can come in handy. Typically, the items are put on a trolley, which is then pulled along with the cable hoist. This can be a time-consuming process, especially if you have a large distance to cover. A cable hoist, however, can make this process much easier. Instead of pulling the trolley, you can simply pull the hoist along with the load. The hoist can also be used to move objects from one location to another. It’s a great way to cut down on time and increase efficiency.

Cable Hoist Safety Considerations

Most cable hoist systems come with safety features like emergency stop buttons, emergency shut-off switches, and warning lights. Make sure these are in place and operating properly before using the system. It’s important that you’re following all recommended safety procedures. For example, according to Industrial Quick Search, electric hoists should only be operated for one minute before being shut off for 99 minutes. Additionally, there are potential hazards that might be present when working near power lines, so cable hoist operators should be aware of them before beginning to work. If you’re working near a power line, you must use a specifically approved cable hoist. It’s a good idea to consult your local authority to ensure you are utilizing the appropriate equipment. To avoid personal injury or damage to property, always use the right load for the job and follow the manufacturer’s instructions.

Types of Cable Hoists

There are several types of cable hoists on the market. A pendant cable hoist is the simplest type and is often used for moving small loads or for minor repairs. This style is suspended from an overhead hook or pole. A lifting beam cable hoist is a more powerful version of the pendant type, with two large wheels that propel it through the air. This type is often used for moving heavy loads and is frequently selected for construction jobs. A belt-driven cable hoist is the most expensive type. It uses a pulley and belt system to lift the load and can be used both indoors and outdoors. Belt-driven hoists are generally rated to operate at a maximum speed of six to eight feet per second, which is comparable to a jackhammer.

If you have questions regarding cable hoists or want to learn more, contact our team at Associated Fuel Systems Inc. As an authorized Stellar Industries dealer, we’re the perfect fit for your project. We look forward to hearing from you!

3 Great Uses for a Stellar Industries Container Carrier

There are many ways to use Stellar Industries container carriers. They’re perfect for all your delivery, switching, and dumping needs. According to Stellar Industries, their range of container carriers can lift, dump, and move up to 8,000 pounds of materials, which makes them suitable for a variety of industries. Here are some of the uses to consider.

1. Moving Bulky Items

As mentioned before, Stellar Industries container carriers can carry loads of up to 8,000 pounds. As such, they are the perfect tool for moving bulky items. For instance, you can use them to move construction debris, metals, and even garbage. These trucks have many uses across all kinds of industries. If you’re in the waste, roofing, scrap metal, or forestry industry, a Stellar Industries container carrier can be a powerful tool. They even come in various sizes, with several hook heights and capacity ratings.

2. Dumping

Looking to use a hook-lift system equipped commercial container carrier as a dump truck? All you need to do is roll on a dump container. These container carriers are perfect for this job. If you’re planning to travel a long distance and need to use a tanker for the job, then the container carrier will do the trick as well. All you need to do is use the hydraulic hoist to roll off the container and then roll on the tanker body. It’s a very simple and fast process. For dumping, you just need to make use of the continuous rotation feature. This enables you to dump from either side. It also has a better ability to distribute a bit more weight to the carrier’s front axle than other models.

3. Container Delivery

Looking to deliver a container? Stellar Industries container carriers can help you deliver items as well! Boasting an 8,000-pound lifting and transporting capacity, the carrier will make an easy job of your container delivery task. They are also perfect if you’re working in tight spaces. These container carriers can connect to a container up to 30 degrees off-center when picking it up. This means you won’t struggle to drop off a container if you’re working on small construction sites.

These are just a few of the ways you can use Stellar Industries container carriers. Are you looking for a truck to use as a dump truck or something to transport and deliver large containers with? Get in touch with Associated Fuel Systems, Inc. We are an authorized Stellar Products Dealer in the state of Georgia, and we’d love to hear from you.

8 Popular Services Offered by Machine Shops

When people hear of a machine shop, they immediately assume it’s a facility where machines are produced. But a machine shop is actually a place where machining is carried out. Machining is a process where parts are fabricated, cut, and finished before being used. These shops can either create new parts or repair existing ones. The people working in these facilities have received special training needed to work in machine shops.

Because of the important role that these shops play, a lot of industries heavily rely on these facilities. This has led to an increase in the number of machine shops in the United States. According to Statista, it’s projected that by 2024, the revenue from these shops will have amounted to about $37.4 billion. With such a huge contribution to the economy, just what services do these shops offer? Here are just a few of them.

1. Field Machining

At times, dismantling a piece of equipment can be uneconomical and impossible. This is where field machining comes in. It allows one to repair equipment without taking it to a repair facility or dismantling it. This process saves money and time. So, instead of the client going to the machine shop, the repairmen go where the equipment is. This service is ideal for emergency repairs, planned shutdowns, and modifications. And since different equipment will need different approaches, find a shop that will formulate a procedure that reduces downtime but still produces results.

2. Maintenance and Repair

For your business to remain competitive, you have to increase equipment efficiency, minimize part replacement, and extend the equipment lifecycle. This can be done through maintenance and repair. Find a machine shop that resolves critical issues in a timely manner, using specialized technology. This will save you time and money.

3. Pressure Testing

Pressure testing usually happens after assembly, machining, or vacuum impregnation. This process is to investigate the integrity of a workpiece to ensure it’s not leaking gases or fluids.

4. Drilling

Perhaps one of the most straightforward services offered by machine shops is drilling. Drilling is all about creating a cylindrical hole in a workpiece. When drilling a workpiece, the waste metal produced is called chips. The drill’s shape allows those chips to fall away from the workpiece, keeping it free from debris.

5. Deep Hole Drilling

This is the machining of holes with a significant depth to diameter ratio. Normal drilling techniques can only give you holes where the depth is five times the hole’s diameter. In deep hole drilling, the depth to diameter ratio can be as much as 150 times the hole’s diameter. Any hole that’s 10 times deeper than the diameter is considered deep. As such, it needs special drilling techniques. The two main methods used in deep hole drilling are gun drilling and BTA Drilling.

6. Jig Boring

Jig boring is a machining process used to enlarge existing holes accurately. The process involves centering, reaming drilling, contouring, counter boring, step boring, etc. A jig boring machine can be used to produce tools, fixtures, jigs, or any other part that requires a high level of accuracy. Jig boring machines resemble jig grinders because they use boring tools while jig grinders use grinding wheels. Also, note that jig boring machines have to be used in a temperature-controlled room. Keeping that temperature constant is what ensures accurate work is done.

7. Broaching

This is a type of machining process involving the use of a toothed tool. Broaching is used when one wants to precisely cut odd shapes like splines, holes, and keyways. This process can shape, smooth, or enlarge a drilled or bored hole. One of the advantages of broaching is that the rate of production is high. It also allows for accuracy, enabling one to achieve a clean and neat surface.

8. Turning

Turning is a machining process performed on a lathe to reduce the diameter of a workpiece to the desired dimension. This operation can be done either manually or automatically. The main disadvantage of doing this manually is that one has to constantly be there for supervision. Automatic turning needs no supervision. With CNC (Computer Numerical Control), you program all the speeds, movement, and tooling changes into your computer. Those instructions are then sent to the machine, and you can focus on other things. CNC allows for efficiency, accuracy, and consistency.

If you have an upcoming project that requires any of the services mentioned, get in touch with Associated Fuel Systems, Inc today. You’ll get quality materials, custom parts, and excellent service.

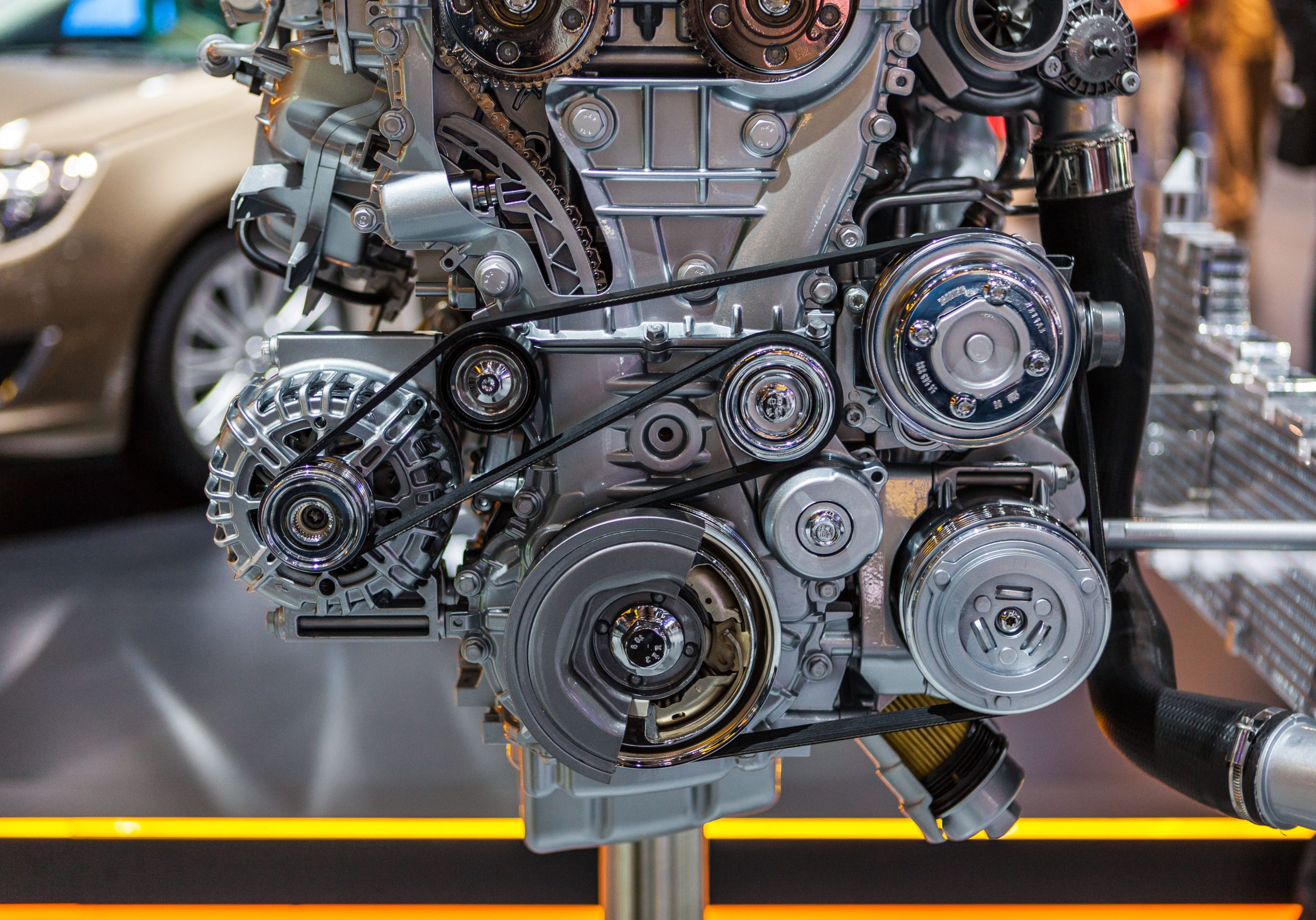

Steps to Take When Your Diesel Engine Needs Repairs

Diesel engines are well known for being heavy-duty and durable. According to Oak Ridge National Laboratory, diesel engines are commonly found in medium and heavy trucks compared to passenger cars in the US. For example, over 70% of trucks with a gross vehicle weight rating higher than 10,000 that were purchased in the United States in 2013 were diesel-powered, which was an increase from 69% in 2009. That said, diesel engines are not invincible, and if you have a diesel-powered car, you might find the engine requires repairs from time to time. Here are the steps to take when your diesel engine needs repairs.

Troubleshoot the Issue

Whenever you encounter a problem with your diesel engine, there’s standard advice you can apply to diagnose your engine. For starters, you can start by checking the engine oil level. Pull the dipstick to ensure there’s enough oil. Otherwise, if there’s not enough oil, your vehicle might not start. In that case, getting the issue fixed might be as simple as topping up the oil.

In another instance, the oil level might be overfull, which is a good indicator of a high-pressure leak. If the engine oil level seems fine, you can perform further diagnosis, depending on your skill level and knowledge of the diesel engine. If you’re a beginner, it’s best to seek repairs immediately from a professional. You can also check your owner’s manual to see if you can get any helpful insights concerning proper repair procedures and when to schedule routine maintenance.

Your diesel engine is what keeps your vehicle moving, but, as mentioned, it can still become faulty. Common repairs that are often diagnosed include oxidized oil, lack of power, oil leakages, exhaust gas recirculation valves, and more. Some components of your diesel engine, like the injection pump, glow plugs, and fuel injectors, may need fixing or replacement to get your engine functioning smoothly. You may not know that this is the issue, but you can watch out for symptoms, such as a diesel engine running at lower RPMs or difficulty in starting your engine.

Search Around for Diesel Mechanics

The next step is to search around for a reputable diesel mechanic that can work on your engine. This is something you should do as soon as possible because professional repair helps increase the life of your diesel engine system, and it’s good for the overall maintenance of your car. A good diesel mechanic can save you from expensive repairs and keep your diesel vehicle running smoothly. When searching for a trustworthy mechanic, a good starting point is to do your research, which you can do online in the comfort of your own home. You can find many mechanics near you and check Google reviews to identify the ones that have a good track record.

Besides the internet, another good starting point is asking your friends and family for recommendations. The people close to you are usually reliable and are more likely to point you in the right direction because they have your best interests at heart. Once you have narrowed down your options, the next step is heading out to discuss your engine. Be sure to ask your mechanic as many questions as possible, such as how many years of experience they have working on diesel engines and whether they have the right training and certification to work on them. Another sign that you have found an experienced mechanic is when they quickly diagnose the problem and suggest the best fix to prevent bigger issues down the line.

Get as Many Quotes as Possible

Diesel engine repairs can get pretty expensive if your vehicle’s engine has developed a serious problem. Fortunately, there’s a way to reduce the costs, and that involves shopping around to get as many estimates as possible. You can then compare the estimates to see which mechanic has the most competitive pricing. That said, price should not be the only determiner when choosing a mechanic. You should avoid estimates that are below the average as this could mean the mechanic uses old or substandard parts. At the same time, you should also avoid estimates that seem to be ridiculously high. Generally, reviewing as many estimates as possible can be a huge eye-opener as it helps you understand the best price to pay to get your engine repaired.

These are the steps you can take to get your diesel engine repaired. Contact Associated Fuel Systems today to get your engine replacement parts from the only certified Stellar Products Dealer in Atlanta and all of Georgia.

Different Ways You Can Utilize a Cable Hoist

A cable hoist can be a handy tool in your shop or garage. It can be used for various tasks from moving heavy objects to suspending items from the ceiling. Here are different ways you can utilize a cable hoist.

1. Suspending Items From the Ceiling

One of the common use for a cable hoist is suspending items from the ceiling. This can be useful for storing things like kayaks, bicycles, and even cars. If you have a high ceiling in your garage, you can use a cable hoist to take advantage of that extra space. Simply attach the hoist to the ceiling and then use it to lift your item up and secure it in place. In addition to saving space, this can also help to keep your items safe and out of the way.

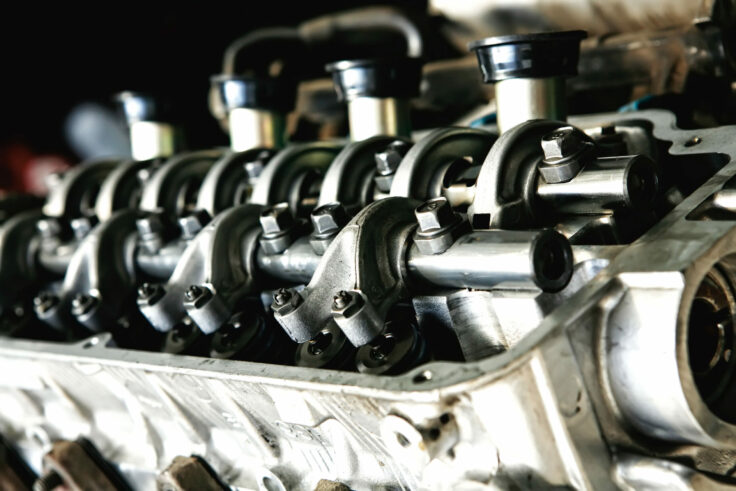

2. Lifting Engines

Another common use for a cable hoist is lifting engines. This can be helpful when you’re doing maintenance on your vehicle or if you need to remove the engine for some reason. Attaching the hoist to the engine and then using the pulley system to lift it up and out of the vehicle can make the job much easier. Diesel engines, for example, are very heavy and difficult to move without a cable hoist. According to the California Energy Commission, diesel has 12% more energy per gallon than gasoline and enhances engine life, making it perfect for heavy-duty vehicle uses.

3. Moving Heavy Objects

If you need to move a heavy object around your shop or garage, a cable hoist can be a big help. For example, if you need to move a large piece of machinery or a stack of lumber, attaching a cable hoist can make the job much easier. Attach the hoist to the object and then use the pulley system to lift and move it to where you need it to go. This can save you a lot of time and effort, especially if the object is very heavy.

A cable hoist is a very versatile tool that can be used for various tasks. Whether you need to lift a heavy engine out of your car or move a stack of lumber around your shop, a cable hoist can make the job much easier. Consider getting a cable hoist if you’re looking for a handy tool to add to your garage or shop. To learn more about using a cable hoist, be sure to contact us today.

7 Common Diesel Repairs

If you’re the owner of a diesel engine, then you know that proper maintenance is key to keeping your car or truck running smoothly. Unfortunately, even with regular care, diesel repairs are sometimes necessary. Here are seven of the most common diesel repairs.

1. Changing the Diesel Fuel Filter

This is one of the most common diesel repairs, and it’s essential for keeping your car running properly. The diesel fuel filter removes dirt and other contaminants from the diesel fuel before entering the engine. If this filter isn’t replaced regularly, it can cause severe damage to your vehicle.

2. Replacing the Air Filter

A diesel engine needs a lot of air to run properly. Over time, the air filter can get clogged with dirt and debris, which can restrict airflow and cause your engine to run less efficiently. Replacing the air filter is a relatively inexpensive and straightforward repair that can make a big difference in how your diesel engine runs.

3. Glow Plugs Repair

Glow plugs are used to help start a diesel engine in cold weather. If your engine is having trouble starting in cold weather, it may be time to replace the glow plugs. This is typically a fairly simple and inexpensive repair.

4. Replacing the Diesel Injectors

Diesel injectors are responsible for delivering diesel fuel to the engine. Over time, they can become worn or damaged, which can cause engine performance problems. If you’re experiencing engine performance issues, it’s worth having your diesel injectors checked by a professional.

5. Lack of Power

When the turbocharger fails, the diesel engine will not produce the power it needs to run. The symptoms of a failed turbocharger include black smoke from the exhaust and a decrease in fuel economy. If your diesel engine has a turbocharger, it is essential to have it replaced as soon as possible.

6. Replacing the Brake Pads and Rotors

If you drive a diesel truck, you know that stopping can be a challenge. That’s because diesel engines generate more torque than gasoline engines, which can wear down your brake pads and rotors more quickly. If your brakes are starting to feel less responsive, it may be time for a brake pad and rotor replacement.

7. Checking the Engine Oil Level

One of the simplest diesel repairs is checking the engine oil level. If the oil level is low, you can add more oil to bring it up to the correct level. This is a quick and easy way to help prevent major engine problems down the road.

According to fueleconomy.gov, diesel fuel contains 10% to 15% more energy than gasoline. As a result, diesel cars may travel approximately 20% farther per gallon than their gasoline counterparts. If you’re looking for a car that’s both efficient and powerful, then diesel is the way to go. For more information about diesel engines, contact us or visit our website.

How to Choose a Certified Diesel Mechanic

Certified diesel mechanics are essential to anyone who owns a diesel car or truck and businesses that own heavy-duty vehicles and equipment. A certified mechanic can help diagnose problems before they cause major damage and reduce the need for expensive replacement parts. Here are some tips to help you choose a diesel mechanic.

1. Don’t Automatically Choose a Mechanic Based on Price

A mechanic who charges the least might not be the best choice. While they may look attractive at first, remember that mechanics need to make a living too, and their rates reflect the time and effort they put into service jobs. A top-notch mechanic may charge a little more, but you can expect them to have the experience and tools necessary to do the job properly. They also know how important it is to keep costs as low as possible.

2. Consider Your Mechanic’s Reputation

Choose mechanics you trust. Trustworthy mechanics should be knowledgeable, courteous, and committed to creating a positive experience for their customers. They also should provide the service history on cars they repair for resale purposes. A certified diesel mechanic will offer basic warranty coverage to ensure you are protected in case of future repairs.

3. Consider the Mechanic’s Experience, Certifications, and Education

A certified diesel mechanic should have specific training and certification in diesel car or truck repair. It’s also important to ensure they stay up-to-date on products and innovations in the automotive industry via continuing education courses. Certified diesel mechanics know how to diagnose and fix problems with your engine correctly.

4. Choose a Mechanic with the Right Tools for the Job

Choose mechanics who go beyond simply ‘having tools’ by ensuring they have modern diagnostic equipment that can detect problems most other shops may miss. A mechanic without adequate equipment is less likely to be able to conveniently inspect, repair, and certify your vehicle.

5. Choose a Mechanic Who Is Willing to Explain What They Are Doing and Why

Even if you are not a diesel mechanic yourself, it is important to understand the basic procedures your mechanic uses. Ask questions and get explanations from your mechanic. Please don’t go with a mechanic who claims you can’t learn anything about what they do or doesn’t give you the tools to make an informed decision.

According to USDOE, diesel is more popular among medium and heavy trucks than passenger cars. For example, in the United States in 2013, 72% of trucks with a gross vehicle weight rating of 10,001 pounds plus were diesel-powered (a 3% increase from 2009). This means that there is an increased demand for certified diesel mechanics.

By choosing a certified diesel mechanic, you are helping to ensure that your vehicle is properly maintained and repaired by someone with the experience and expertise needed to do the job right. Call us today to learn more about our services and how we repair and maintain diesel vehicles of all types.

What You Need to Know About CNG Engine Maintenance

Different vehicles operate on different types of fuel. Nonetheless, the use of diesel-fueled cars has been seen to be embraced by many compared to gasoline. According to the California Energy Commission, diesel has turned out to be the fuel of choice because it can be used by heavy-duty vehicles since it has an extended engine life. Moreover, compared to gasoline, diesel contains more energy per gallon of up to 12%. However, despite all this, more and more people are now transitioning to using compressed natural gas (CNG) with their engines. It has proven to have running costs compared to any other type of fuel. This is why we will talk about CNG engine maintenance for those who are using it or are planning to use it in the future.

When you think about engine maintenance, it usually brings to mind oil changes and tire rotations. However, compressed natural gas (CNG) engines come with their unique challenges requiring regular attention. The good news is that by following a few simple guidelines, you can ensure your CNG vehicle runs like the day you bought it for many years to come.

Have Your Cylinder Pressure Tested At Least Once Per Year

All cylinders should be carefully inspected annually regardless of use. However, they are essential if your car is used as a daily commuter because the elapsed time between inspections will be much shorter. That’s why CNG engine vehicles are built with two-way communication systems between the engine control unit (ECU) and the cylinder pressure sensors. This way, if there is a problem with the CNG cylinder, it will be detected immediately, and appropriate action can be taken before any major issues arise.

Cylinder Rust Removal

It may seem odd that rust could cause natural gas tank problems, but it’s not out of the question. As water accumulates inside gas tanks from condensation or exposure to humid environments, corrosion may form on metal components, including the cylinder walls and valve stems. This accumulation of rust can lead to a host of issues, including compromised welds, cylinder leaks, and even tank ruptures.

Look Out For Damage

When it comes to damage caused by accidents or environmental exposure, it is a good idea to have a professional inspect your CNG vehicle. For example, suppose you were in a collision, and the frame of your car sustained structural damage during the wreck. In that case, there is potential for this compromised section of your vehicle to puncture one or more cylinders upon impact, which would understandably put your safety at risk as well as require the replacement of multiple components.

Watch Out For Leaks

Unfortunately, not all gas leaks are easily seen with the naked eye. Leaks have a way of sneaking up on you, especially those which go unnoticed for long periods. When your CNG vehicle is being refueled or filled from a pressurized nitrogen canister, you will likely hear an audible hissing noise from the pressure vent on the side of your car. This vent helps relieve excess pressure from the tank to maintain safe levels for transport and is not considered a leak. But any time you notice this noise while your car is parked or idling, there could be a severe problem with one of your CNG cylinders which require immediate attention.

Follow these simple steps for optimal CNG engine care throughout your vehicle’s life cycle. Have a professional inspect your gas tank annually to ensure that it is in good working order. In addition, look out for odd sounds while refueling your car (which may indicate potential problems), and avoid parking over unstable surfaces, which could lead to leaks caused by ground shifts or erosion.

If you are experiencing any issue with your CNG engine that calls for maintenance, do not hesitate to contact us. We will gladly be of service to help you remedy the problem. Our company has been in service for quite some time now. Thus we guarantee you nothing but quality services.

Diesel Transmissions: Keep an Eye Out for These Symptoms

A diesel vehicle is often a significant investment, as their fuel contains between 10-15% more energy and can go around 20-35% further on a tank of diesel than a gasoline vehicle (per the EPA). However, they also have problems, such as issues with diesel transmissions that may make your car run roughly. Here are a few symptoms to watch out for when running your high-quality diesel vehicle.

Difficulty Shifting

Most diesel vehicles have a manual transmission, making them quite fun and sometimes even challenging to drive. They should shift quite smoothly once you get the hang of it, though. However, if you struggle to shift (particularly in trickier areas), you probably have a problem with your transmission. Slipping gears almost always indicates a significant problem with your transmission.

Bizarre Noises

Your diesel vehicle will make plenty of noises as it drives. That’s nothing too unusual. However, you might notice some unpleasant transmission noises that can be a pretty big sign of issues as you ride. For example, humming, clunking, and whining noises usually indicate a myriad of problems. Usually, they show problems with the fluid pump that may cause diesel transmissions to fail on you.

Unappealing Smells

When you shift your vehicle and drive for a long time, do you notice a rather unpleasant, burning smell? That may be your transmission fluid overheating and breaking down on you. This problem usually occurs if your fluid is old, and you don’t change it regularly enough. Replacing it may help here, though you may have already done too much damage to your transmission and need repairs.

Shaking or Vibrating Sensations

Does your diesel shake or vibrate when you try to change gears? There could be a few things wrong here. The most likely problem is your transmission, as it may cause diesel to run poorly. However, you may also have issues with your suspension. The easiest way to tell is to gauge when the shaking begins. If it occurs when changing gears (and not while otherwise driving), it’s your transmission.

If you experience any of these symptoms with your diesel transmissions, it is essential to talk to a mechanic or repair shop right away to minimize any dangers. These professionals will work with you to help you understand what is happening. Then, if necessary, they’ll replace your transmission and provide you with a stronger and more secure vehicle. Doing so will help to ensure you get the best results possible.