The Benefits of Owning a Diesel Vehicle

If you’re considering purchasing a diesel truck, there are a few things you should know. Diesel engines are vastly different from gasoline engines. A first-time diesel owner needs to learn about how to care for their vehicle and what’s different between it and other vehicles. According to the California Energy Commission, diesel fuel is the second largest transportation fuel used in California. Here are a few things you should know about this type of engine.

Better Power

Your diesel vehicle will provide greater power as the amount of torque produced is far greater than that of gas engines. This is helpful for individuals who use their vehicles to pull heavy loads or do other types of work.

Faster Shifting

You might also notice when you drive a diesel engine that you’ll get faster shifting. You’ll see that shifting movement happens faster in a diesel vehicle. This is because this type of vehicle requires less RPMs and that results in less shifting time.

Lower Fuel Usage

A lot of drivers are switching to diesel because these vehicles provide lower fuel usage. In this day of increasing fuel costs, this is an important consideration. Using less fuel not only ensures you’re saving money but also contributes to a greener planet.

Cleaner Fuel

Diesel also has lower emissions and clean diesel creates better fuel economy all around. In addition to this, diesel engines also run more cleanly thanks to the newly mandated EPA regulation of using Ultra Low Sulfur Diesel. You can use a diesel vehicle today and feel confident about your environmental impact.

Better Savings

Because you’ll be using less fuel, you’ll start to see fuel savings quickly. In addition to this, diesel engines also last longer, making the need for vehicle replacement less frequent. This is really where the savings come in because you’ll be able to drive your diesel vehicle longer and drastically cut your transportation expenses this way.

These are just a few things that you need to know as a new or potentially new owner of a diesel vehicle. If you’re looking for diesel engine services, please contact our team at Associated Fuel Systems Inc today. Our team of experts is happy to answer any questions you may have about owning a diesel vehicle. We are here for your automotive needs.

7 Questions That’ll Determine the Best Diesel Mechanic for the Job

The heavy-duty diesel engine manufacturing industry is a growing market. In fact, according to IBISWorld, it made $30.9 billion in 2022. If you’re looking for a machine shop to repair your diesel vehicle, you want to make sure that the mechanic you hire is qualified, knowledgeable, and reliable. Here are seven key questions you should ask a machine shop to ensure you make a good choice.

1. Do You Specialize in Diesel Vehicles?

When you take your vehicle to a machine shop, you want someone who knows exactly how your specific vehicle works and what they need to do to make it run perfectly. There are a lot of different manufacturers and engine types. You wouldn’t want someone with general knowledge about regular engines working on a diesel engine!

2. What’s Your Labor Rate?

How many times have you heard about people taking their vehicle to a diesel repair shop and being stunned at the bill? That’s because they didn’t do any research beforehand or ask what the mechanic charged for their labor. If you ask what the labor rate is ahead of time, you can properly budget before you get that bill. See if you can get an item-by-item listing of all the services you may need before you sign anything.

3. Will You Communicate Each Issue?

When it comes to repairing a diesel vehicle, issues can crop up out of nowhere. You might bring your vehicle in to have one part of it repaired; however, there might be something else going on that, if not repaired, could wind up causing even more of a problem. Your mechanic should be able to give you plenty of warning about anything that also materializes.

4. What Are My Repair Options?

With some repairs, there may be multiple solutions. You want to see how far outside the box your potential mechanic will be able to think. They might be able to come up with something that other professionals might not even consider. Any diesel mechanic should also consider their audience, as some drivers aren’t that familiar with what goes on under a hood. The mechanic should be able to explain repairs in a way that’s easy for you to understand. They should also clarify anything that you’re puzzled about.

5. Can You Provide a Maintenance Plan?

Getting your diesel vehicle serviced is only one part of the equation. A mechanic will be able to fix any issues you come in with. They should also be able to outline a plan for you so that you’re able to keep your vehicle running smoothly between visits. They can give you a checklist of various parts that you should bring in for maintenance at certain intervals. This way, you can be a safe driver on the road!

6. Are You Certified?

Capital One reports that diesel trucks can last well over 400,000 miles! However, keep in mind that it takes quite a bit of maintenance and care to hit this high number. If you want your own diesel vehicle to last this long, it’s crucial to hire a certified diesel mechanic. Be sure to ask about certifications before you bring your vehicle in for any repair or maintenance services.

7. Does Your Shop Use High-Quality Parts?

Your diesel vehicle is only as good as its parts. When you call a machine shop, inquire about the quality of the parts used when they complete repairs for customers. Do they use quality parts that the diesel industry recognizes? Cummins, Detroit Diesel, Caterpillar, Doosan, International, and John Deere are some of the most recognized manufacturers that any diesel mechanic should be aware of.

By asking these seven questions and more, you can easily narrow down which shops are worth considering. Hire the right diesel mechanic to perform dependable repair and maintenance services. Don’t be afraid to ask questions, as they can help you avoid making an expensive mistake! If you reside in Conley, GA or a surrounding area, look no further than our qualified team at Associated Fuel Systems Inc. Our certified machine shop specializes in truck and body services, sales, and more. Contact us today to learn more about how our diesel mechanics can assist you with ease!

6 Benefits of Owning a Diesel Truck

Diesel trucks remain a favorite for their fantastic horsepower. They are the workhorses of the road, helping to perform important jobs like towing vehicles and delivering groceries. More people than ever are relying on these high-performance vehicles to get the job done. Keep reading to learn about several benefits you’ll enjoy when you choose these quality trucks.

1. Greater Fuel Efficiency

Diesel engines are known for being more efficient than other gasoline engines. That’s because diesel fuel contains more energy per gallon, so you don’t need as much fuel to go as far. According to Progressive, diesel vehicles typically cost more but get better mileage than gas vehicles, with some diesel-powered cars getting up to 50 mpg or more!

2. Higher Torque

The towing capacity of diesel engines remains unrivaled. These engines are designed to pull heavy loads, making them ideal for hauling almost anything. This is why they’re the first choice for tow trucks, work trucks, and other vehicles with heavy loads.

3. Excellent Durability

Diesel engines are known for their ability to haul heavy loads because that’s what they’re designed for. These engines can handle the stress of towing everything from cars to recreational vehicles, which means they won’t give out or need repairs because of the stress. This makes them far more durable than other options.

4. High Resale Value

Cars and trucks usually depreciate as soon as you start driving them. However, diesel trucks are known for retaining more of their value than other options. That’s because these trucks are always in high demand. Their exceptional durability means they don’t lose value for having high mileage like other vehicles.

5. A Cleaner Burn

Diesel fuel was once known for harming the environment, but now it has a cleaner burn than many other fuel types. This helps ensure that these engines aren’t damaging the environment when people use them. Many truck owners use additives to ensure the fuel continues to burn clean.

6. Easier Maintenance

Maintenance on diesel engines is relatively simple. For starters, they don’t have spark plugs, eliminating some of the care you must perform on other vehicles. Changing the oil is also relatively simple, making for a convenient and seamless automotive experience.

Diesel trucks remain a favorite because of their extreme durability and long engine lifespan. They are essential for getting tough jobs done and going the distance when you need it most. Contact AFS DIESEL to get started with a vehicle you can depend on!

5 Things a Good Truck Shop Should Offer

Not all truck shops are the same. In fact, some are just better than others. Good truck shops should have everything you need to maintain and repair your rig. They should also be experts in handling the equipment they use. For example, according to Industrial Quick Search, it’s advisable to operate electric hoists for one minute only and then turn them off for 99 minutes. This is the type of information that staff at good truck shops should know. Do some research before settling on the right shop for you. Here are a few things to look for when making your decision.

1. Decades of Experience

Proper transmission and engine repair for diesel engines isn’t a skill that’s developed overnight. The best truck shops have decades of experience. When you need to find a shop for maintenance or repair for your rig, be sure to ask how long they’ve been in business. Longevity is also a good indication that they have great business skills and are adept at keeping customers satisfied year after year. Don’t overlook this important aspect when you’re determining which shop is right for your needs. The longer a shop’s been in business, the better.

2. A Substantial Inventory of Parts

Engine and transmission parts are vital to keep diesel engines running. You don’t want to get to a shop only to find out that they don’t have any, or very few, parts in inventory. A substantial parts inventory means that they can get to your rig and get it fixed right away. Ordering parts, especially for specialized engines, can take a lot of lead time. You don’t want to have to wait for days or weeks for parts delivery. To avoid a situation like this happening to you, be sure to choose a shop with a significant number of commonly needed parts in their inventory.

3. Preventative Maintenance

In addition to repairs, your shop should also be able to handle your truck’s maintenance needs. When a truck is out of commission, it means money isn’t being made. One of the most effective ways to keep a truck on the road is to give it the ongoing maintenance it needs. Having to deal with one shop for repairs and another for maintenance isn’t an efficient way to handle things. When you’re selecting which truck or semi-shop is right for you, be sure that they’re able to provide the maintenance services you need.

4. Transmission Service and Repair

The transmission systems in diesel trucks require a highly skilled mechanic to keep them running properly. Service and repair of your transmission are what will likely send you to the truck shop. Discuss their service levels before selecting a garage, as you don’t want to work with anyone who doesn’t fully understand how to keep your transmission system properly maintained. Repairs need to be done the right way the first time. Any shop worth their salt has at least one transmission specialist on staff. Make sure to ask questions that will reveal their level of experience and expertise. You won’t regret it!

5. Engine Repairs

Finding the right shop for your truck’s diesel engine repairs can take some time. However, any time you spend researching and exploring potential garages will be well worth it. You entrust your shop with your rig. Without your rig working properly, your earnings will be affected. Spend some time at the garage to get a first-hand look at how they operate and how they handle engine repairs. This will allow you to make an informed choice. Not every garage has what you need, but when you find one that does, you’ll know they’re the one for you! Engine repairs should be completed efficiently and completely and at a fair price. Now’s an ideal time to find the right garage for your unique needs.

Comparing local truck shops takes some effort, but it’s worth it. Our shop has everything you need to keep your diesel engine running properly. Any time your rig has a transmission or engine problem, we’re the shop to bring it to. We provide professional services that reflect our decades of experience. The next time you need maintenance or repair services, we’re the shop to call. Contact us today at AFS DIESEL Truck & Body to learn more about our products and services. We’ll have you back on the road again in no time!

5 Things to Consider When Looking for a Diesel Mechanic

If your company relies on vehicles with diesel engines, you’ll need to find a reliable mechanic you trust to work on them. After all, your vehicles are often the backbone of your business. Diesel vehicles have several great properties, including 12% more energy per gallon than gasoline and the ability to extend engine life, according to the California Energy Commission. However, diesel engines also require a high level of expertise, beyond that of a standard mechanic. If you’re on the hunt for a diesel mechanic, here are a few key considerations to keep in mind.

Vehicle Specialization

If your livelihood revolves around tow trucks, dump trumps, garage trucks, semi trucks, or other diesel-powered vehicles, you need to find a mechanic who is a specialist in this area. When you find an expert in commercial vehicles, you can rest assured that they’ll have all the experience necessary to keep your vehicles — and business — running smoothly.

Certifications

A reputable and certified diesel mechanic should have the necessary certifications that prove their knowledge of diesel systems. If you are looking for specialty parts, you should make sure they have experience using them. This is a crucial factor to consider when finding a business you can count on to keep your vehicles on the road.

Access to Quality Parts

Many commercial vehicles need specific and durable parts to withstand daily use. You’ll want to ensure your chosen mechanic has consistent access to high-quality parts from reliable brands. If your chosen mechanic is licensed to sell Cummins parts, you can trust them to produce incredible results.

Turnaround Time

Like any business owner, you probably know that time is money. A good diesel mechanic understands this urgency and is able to provide swift and thorough repairs. A quick turnaround time will ensure downtime is minimized so you can quickly put your trucks back in action. You should also check to see if they’re able to come to you to perform onsite machine work, minor repairs, and preventative maintenance.

Are you looking for a reputable and certified diesel mechanic in Georgia? AFS DIESEL Truck & Body is here for you! We are proud to be the only dealer licensed to sell Stellar Industries products in the state. Give us a call today to get started!

What to Know Before Using Diesel Engines

Diesel engines are used for a variety of vehicle and equipment types. Many drivers choose to purchase vehicles that are fueled by diesel because of the variety of benefits they offer drivers. If you’re considering investing in a diesel-powered vehicle, it’s essential to learn as much as you can about them. Read on to learn more about things that you should know before purchasing or using diesel engines in order to make an informed decision and maximize the benefits of diesel power.

Fuel Efficiency and Power

One of the significant advantages of diesel engines is their fuel efficiency. Diesel typically costs more than regular gas, which makes people think it’s more expensive. However, according to Progressive, diesel-powered engines typically offer better mileage compared to gas vehicles. This makes them an attractive choice for those seeking long-term cost savings.

Diesel fuel has a higher energy density, meaning it can generate more power per unit of fuel. This translates to improved torque, allowing diesel engines to excel in applications that require high pulling power or heavy loads. Whether you’re using a diesel-powered engine for transportation, industrial equipment, or marine vessels, their fuel efficiency and power characteristics make them a reliable and economical choice. Be sure to talk with your local diesel vehicle seller to learn more about the fuel-efficient options they have in stock.

Maintenance Requirements

Proper maintenance is crucial for the longevity and performance of diesel engines. Unlike gasoline engines, these engines often require more frequent oil changes and fuel filter replacements. This is important to know as it can increase your overall maintenance costs and downtime. Regular maintenance tasks include checking and cleaning the air filters, inspecting the cooling system, and monitoring the fuel injection system.

It’s important to follow the manufacturer’s recommended maintenance schedule and use quality lubricants and filters to ensure optimal engine performance. Additionally, these engines may require occasional maintenance on components such as glow plugs or injectors, which should be inspected and serviced as needed. By staying proactive with maintenance by working with a reliable diesel engine service technician, you can maximize the lifespan and reliability of your diesel-powered engine.

Performance Characteristics

Diesel engines offer distinct performance characteristics compared to gasoline engines. They typically deliver more low-end torque, providing better acceleration and towing capabilities. Diesel-powered engines also tend to operate at lower revolutions per minute (RPMs), resulting in a smoother and quieter ride.

However, it’s important to note that these engines may have slower throttle response when compared to gasoline engines, which can impact their overall responsiveness in certain situations. Understanding these performance differences is crucial, especially if you’re transitioning from a gasoline-powered vehicle to a diesel-powered one. It’s recommended to test drive diesel vehicles or consult with experts at your local vehicle dealership to ensure the performance characteristics align with your specific needs and preferences.

Environmental Impact

While diesel engines offer advantages in terms of fuel efficiency and power, it’s also important to consider the environmental impact of this vehicle type. Diesel exhaust emissions contain particulate matter and nitrogen oxide (NOx), which can contribute to air pollution. However, technological advancements, such as diesel particulate filters and selective catalytic reduction systems, have significantly reduced these emissions in newer diesel engines.

It’s important to understand the emission standards and regulations in your region, as they may affect the availability and usage of diesel engines. Additionally, the availability of ultra-low sulfur diesel (ULSD) fuel is essential, as modern diesel-powered engines require this cleaner fuel to meet emission standards. When you visit your local vehicle dealership, talk to an expert about the potential environmental impact and how to ensure you’re meeting the emission standards for your area.

Diesel engines can provide significant benefits for vehicle owners. It’s vital that you take the time to consider all the factors that can be impacted by choosing to purchase a vehicle of this type by talking with professionals who understand diesel engines. Being knowledgeable about these key aspects will help you maximize the advantages of diesel power while ensuring proper maintenance and compliance with regulations. If you are in the market for a new vehicle with a diesel-powered engine, reach out to Associated Fuel Systems Inc today! Our team can help you find the one that’s right for you and your needs.

3 Questions to Ask Truck Shops During Repairs

Truck shops specialize in truck repair. Some of the shops offer machining services, while others don’t. According to Statista, by 2024, the machine shop industry will be valued at about $37.4 billion. Likewise, some shops can work on some trucks but can’t work on all types of trucks. You should ask your local truck shops three questions before you leave your truck in their care.

1. How Much Will the Repair Cost?

Shopping around for a good deal when you need truck repairs is fine but keep this in mind. The lowest cost is not always the best value. You should consider the experience of truck shops, the reputation of the shop, and the services they provide as part of the price quote. Don’t get stuck on the lowest price possible or you risk getting the quality repairs you need. It’s better to consider the big picture to find the best deal.

2. How Long Will the Repairs Take?

Once you find a shop that meets the right criteria with the right experience in making the repairs you need and a strong reputation for delivering the work as promised, you need to ask how long the repairs will take. Reliable truck shops are in high demand. Knowing how long you can expect to be without your truck is important. A solid ballpark estimate of the time it will take to make the repairs will help with planning.

3. What Happens if Something Else Goes Wrong?

Let’s say you take your truck to the truck shop for diagnostics, and the mechanic diagnoses the problem. You come to terms with repairs, but what if something else is wrong with the truck? How is that handled? Typically, truck shops know what they’re doing. They’re usually right on target if they say that something specific is wrong with your truck. However, there are rare occasions when one thing is repaired, only to find that something else is wrong. Always trust a professional’s judgment when it comes to repairs. They are professionals for a reason!

Asking the right questions is essential to being on the same page. The right shop will be happy to answer all your questions and be transparent with the answers. Contact us today at Associated Fuel Systems Inc.

What Is a Hydraulic Hooklift Hoist?

Have you ever wondered how heavy machinery is loaded onto the back of a flatbed truck? A hydraulic hooklift hoist is the answer! A hydraulic hooklift hoist is a device that can be used to quickly and easily move large and heavy items, such as construction equipment, onto the back of a truck. It works by using hydraulic cylinders to lift and lower a metal platform, which is equipped with hooks that can then be used to easily attach the equipment. Below is everything you need to know about these hoists, and where you might use them for your projects.

High Capacity for Loading and Dumping

Hydraulic hooklift hoists usually have a large capacity for loading and dumping. According to some estimates, this can be as high as 8 thousand to 68 thousand pounds. Loading and dumping have two distinct processes. When loading, the heavy object is lifted off the ground and hooked onto the platform. Then, hydraulic cylinders are used to raise the platform so that the item can be loaded onto the flatbed. For dumping, the platform is lowered and the hooks are used to unhook the heavy object and deposit it into the desired location.

Flexible and Versatile Design

Hydraulic hooklift hoists are designed to be flexible and versatile. They can be used in a variety of settings and applications, such as construction sites, industrial yards, and agricultural areas. Additionally, they are not limited to just one type of vehicle; they can be mounted on a variety of trucks and trailers, making them extremely versatile. They can also be used to load and dump various items. For instance, shipping containers are a common type of item that can be easily loaded and unloaded using these hoists. Flatbeds on trailers can also be used to transport large, heavy items such as vehicles. Yet another use for them is loading and dumping large dumpsters. These dumpsters can range up to 40 tons, making them extremely heavy and difficult to move without the help of a hydraulic hooklift hoist.

Safety Considerations

Hydraulic hooklift hoists also come equipped with various safety measures to ensure the safe and secure loading and dumping of heavy items. For instance, they typically have an emergency stop button to ensure any accidental movement is stopped immediately. Hoists are also equipped with cab controls, which can help control the movement of loading and dumping. Cab controls can be controlled by cables, air, or electronic systems. According to Industrial Quick Search, electric hoists should only be operated for one minute before shutting off for 99 minutes. On the other hand, cable controls can be used in various conditions, including during winter and cold extremes. Other safety considerations include using fall protection, wearing safety glasses, and observing all forklift operation guidelines.

Single and Dual Cylinder Designs

There are two different types of hydraulic hooklift hoists available: single-cylinder and dual-cylinder. Single-cylinder hoists use one large hydraulic cylinder to lift and lower the platform, while dual-cylinder hoists use two cylinders. Generally speaking, the single-cylinder design is cheaper and does a good job at basic loading and dumping functions. However, these designs are a bit unstable on uneven ground, which is why you won’t typically see them on newer construction sites. Dual load and dump cylinder designs are far more stable and, although a bit more expensive, remain a good choice for those with extensive renovation and construction projects ahead.

Where to Find Hydraulic Hooklift Hoists

Hydraulic hooklift hoists can be purchased from a variety of retailers, both online and in person. It’s important to consider the size and capacity you will need for your project when choosing one. For instance, you can find hoists with low capacities of 4 thousand pounds, or you can shop for those with higher capacities for bigger shipping containers. Additionally, you can rent a hoist, which is often the most cost-effective option for short-term projects.

Hydraulic hooklift hoists are an invaluable tool in many industrial and construction settings. They can be used to quickly and safely load and dump heavy items onto the back of a flatbed truck, making them incredibly useful for a variety of projects. By understanding the key features and safety considerations associated with this type of equipment, you can make an informed decision when purchasing or renting one. If you’re looking for a hydraulic hooklift hoist, Associated Fuel Systems Inc offers a wide range of options to meet varying needs. Contact us today to learn more!

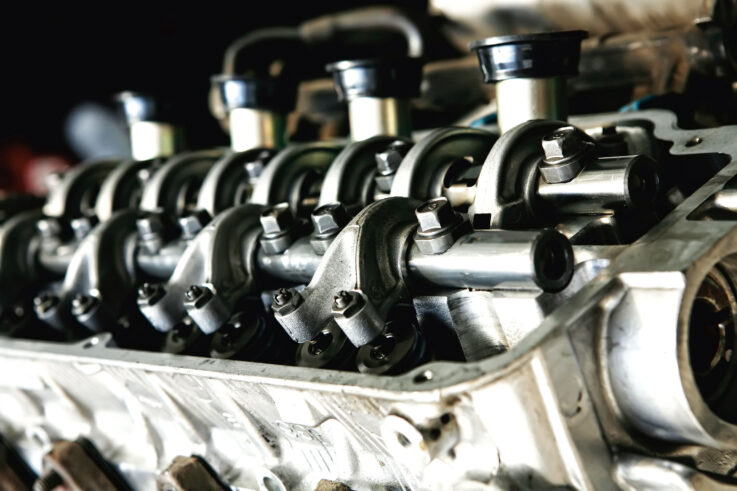

The Unique Qualities of Working with a Diesel Engine

There’s a reason only a certified diesel mechanic should work on your diesel engine. Gas-powered engines and diesel engines are similar but not the same. It could be argued that these two types of engines are more different than they are alike. Here are a few unique qualities you’ll find in a diesel engine that should convince you to hire only a certified diesel mechanic to work on yours.

Diesel Fuel is More Economical Than Gasoline

Diesel engines are designed to extract more energy from the fuel. Diesel engines have a much higher compression rate. According to the Department of Energy, you can expect to get 10-15% more energy out of diesel fuel compared to gasoline. Vehicles outfitted with diesel engines can go about 35% further on the same amount of fuel as a gas-powered engine. In other words, one gallon of diesel fuel will get you much further than one gallon of gasoline.

One of the unique characteristics of a diesel engine that requires the care of a certified diesel mechanic is the compression ratio of the engine. Of course, that’s not the only factor that a mechanic has to be aware of when it comes to the unique characteristics of a diesel engine.

There are No Spark Plugs

If you’re looking for a diesel engine tune-up and want to change the wires and plugs, you’re out of luck. Diesel engines don’t have spark plugs. As a matter of fact, diesel fuel isn’t easily ignited. If you drop a match into a puddle of diesel fuel, the flame of the match will be extinguished.

As previously mentioned, a diesel engine has high compression. A diesel engine relies on a compression ignition and glow plugs to heat the combustion chamber. A gasoline engine depends on spark plugs to ignite the compression of the engine. Both compression ignitions and glow plugs are characteristics unique to a diesel engine.

There’ll Be Dual Thermostats

Large diesel engines have two thermostats. In almost every gasoline-powered engine, there’s only a single thermostat. Large diesel engines, the types you find in trucks and farm equipment, use a dual thermostat system to keep the engine cool.

This dual thermostat system is a unique feature of diesel engines. Diesel engines run hotter than gasoline-powered engines. The dual thermostats are an added safety feature to protect the diesel engine. The primary thermostat and the secondary thermostat work together to ensure that the engine is cooled properly.

There’ll Be a Water Separator

Another unique characteristic of the diesel engine is the water separator system. Diesel fuel is not hygroscopic, which means it doesn’t repel water the way gasoline does. The water separator system helps to protect the engine from water and other contaminants that may be in the fuel.

The water separator system needs maintenance. A certified diesel mechanic can perform that maintenance. This part is an essential part of any diesel engine.

There Will Be Some Similarities

There are many different and unique characteristics of a diesel engine that a certified diesel mechanic will know how to address, but there are some things that are true for any type of fossil-fueled engine. For example, both gas-powered and diesel engines need regular maintenance.

Both a gas and a diesel engine need to have the oil regularly changed. In both types of engines, engine oil serves as a lubricant. However, oil in your diesel engine does more than lubricate the engine, it lubricates the turbocharger, which means it’s critical that you have regularly scheduled oil changes for your diesel engine.

Both engine types need fuel filter maintenance, but it’s critical that you change both of the fuel filters on your diesel engine every 10,000 miles under normal driving conditions. You’ll have to do this more frequently if you’re towing heavy loads.

Air filters also need to be changed on both types of engines. On a diesel engine, your air filter should be changed every 10,000 miles or when the filter gets dirty. There are maintenance needs for a diesel engine and a gas engine that are similar, but how those needs are carried out is unique.

If you own a diesel engine vehicle, you should have a certified diesel mechanic manage your maintenance and repairs to ensure that your engine gets the best possible service. That’s where we come in! Don’t risk the health of your engine. Contact Associated Fuel Systems Inc today to learn how we can help you.

Pursuing a Mechanic’s Career in the Modern Market

Pursuing a career as a mechanic is an excellent way to secure a stable and rewarding job. This profession requires technical knowledge and mechanical skills, but it also offers plenty of opportunities for those who are willing to learn. In the modern market, there is an increasing demand for mechanics and machine shops. Let’s learn more about the career opportunities that come with being a mechanic and what it takes to succeed in this field.

1. Education Requirements

To become a professional mechanic, an individual must have a certain level of education and training. The most common path is to complete an apprenticeship or join a two-year technical college program. During this time, mechanics will learn about the various components of machines and their uses, as well as how to diagnose and repair them. They will also gain experience in problem-solving and troubleshooting. After completing the educational or training program, mechanics can take certification tests to become certified in the fields of automotive and heavy equipment service.

2. Job Opportunities

Mechanics have plenty of job opportunities available to them in the modern market. They can work in automotive repair shops, machine shops, or even be employed by large corporations. They also have the option of opening private businesses or becoming a freelancer. With the right qualifications and certifications, these professionals can even find employment in areas like aerospace engineering or robotics.

3. Increased Demand for Mechanics

The demand for these experts is on the rise due to the increasing complexity of machines and the need for maintenance and repair. According to Statista, the revenue of machine shops in the U.S. will amount to approximately $37.4 billion by 2024. A skilled and certified mechanic will continue to be in high demand as companies look to meet the growing need for mechanical devices. Those interested in pursuing a career as a mechanic should prepare for the increase in job opportunities. The chance to make a solid income in this field is extreme.

The modern world needs mechanics like never before. Those willing to learn the necessary skills and qualifications can find plenty of job opportunities in this field. With the right education, certifications, and experience, mechanics can look forward to a rewarding and stable career. Contact our team at Associated Fuel Systems Inc. today for more information.